- E-mail: jason@lisn-machinery.com

- Tel: +86 185 1618 2855

1). PLC control system with touch screen

2). Independently controllable heating zones, heated by far infrared ceramic heating bricks

3). Pneumatically powered clamp frame

4). Automatic cooling system with industrial chiller and spray guns

5). Automatic vacuum forming system

PRODUCT DESCRIPTION

Machine video on Youtube:

Application:

The material such as PP, PE, PS, PLA, PVC, PET, PETG, EPS, HIPS, HDPE, PMMA in soft film could be processed by this machine, it is an ideal full auto vacuum forming machine for blisters, clamshell, plastic containers, fruit trays, egg trays, dishes, bowls, lids, medical packaging such as ampoule trays and vial trays, etc.

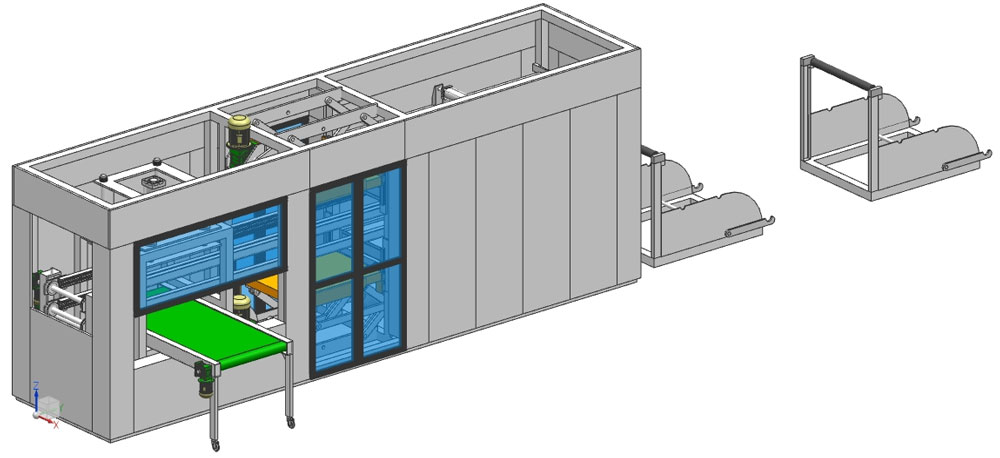

1. Outline:

The equipment consist of heating system, forming system, vacuum system, pneumatic system, cooling system and control system with reasonable structure. It is designed in line with the principle of energy saving and its production speed is 60% faster and 50% energy saving than single station thick sheet vacuum forming machine. It is easy to operate with HMI. The machine has acquired a number of national patents, it can be customized according to customers’ requirement.

1.1 Basic units:

1). PLC control system with touch screen/HMI

2). Independently controllable heating zones, heated by heated by Elstein ceramic heaters

3). Vacuum integrated high Pressure Forming system

4). Accurate and stable cutting & stacking system

5). Pneumatic system & vacuum system

1.2 Main features:

1). It is suitable for male mold and female mold forming, which adopts the integration of positive and negative air pressure to ensure good molding quality and precise molding size.

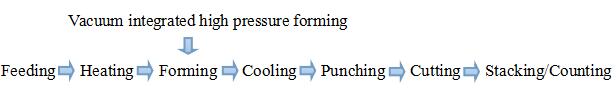

2). Processing flow: Auto Feeding → Heating → Forming → Cutting → Stacking → Counting → Waste Material Winding

3). This machine consists of Heating system, Vacuum integrated high Pressure Forming system, Pneumatic system and PLC Control system.

4). Feeding, punching, cutting & stacking adopts servo motor control, high speed and accurate.

5). Forming, punching and cutting station is driven by eccentric crank linkage structure, controlled by Delta/Mitsubishi servo motor. Guiding pillars made of superior quality bearing steel Gr15 and hard chromium plating, designs for good rigidity, accurate performance and excellent abrasion resistance, which contributes to the working life of equipment.

6). The bushing of crank linkage mechanism is made of superior quality quenched and tempered steel 40Cr, which is imported from Japan, designed for high rigidity, good resistance of abrasion and pressure, which ensures more than 40000 hours working life.

7). Tool change system of optimized ergonomic design which shortens the time for tool change.

8). Apply air pressure to release the molding from the mold, damage of the molding in the releasing process is avoided.

9). Machine cycle status is clearly visible at a glance and all parameters can be adjusted in real time without interrupting the current cycle.

10). The PLC program offers saved memory for project to project recognition.

11). Imported electrical and pneumatic components from international well-know manufacturer make the machine features reliable quality and wearing well.

12). Special chain rail, no deviation and vibration, wearing well. Guide rail adopts toothed roller chain, cooling pipelines inside the aluminum alloy beam, high cooling efficiency and save water.

2. Main technical parameters:

| Model | LS-610 |

| Applicable material | PP, PE, PS, PLA, PVC, PET, PETG, EPS, HIPS |

| Max forming size | 650×650 mm |

| Max forming height/depth | 120 mm |

| Max roll sheet diameter | Φ600mm |

| Sheet width | 460~660 mm |

| Thickness of sheet | 0.15~2.0 mm |

| Stroke of top mold | 120 mm |

| Stroke of bottom mold | 120 mm |

| Max cutting force | 80 Tons |

| Power supply | 3P 380V AC 50/60Hz or customize |

| Control power supply | 24V, DC |

| Max power consumption | 100KW |

| Air pressure | 0.6-0.8 Mpa |

| Mold table driven by | Air cylinder, Crank arm & Connecting rodMax drive 1000KG |

| Forming method | Vacuum forming |

| Vacuum pump | R 5 RA 0100F Pumping speed: 100m3/h3KW |

| Working speed | 10~15 cycle/min |

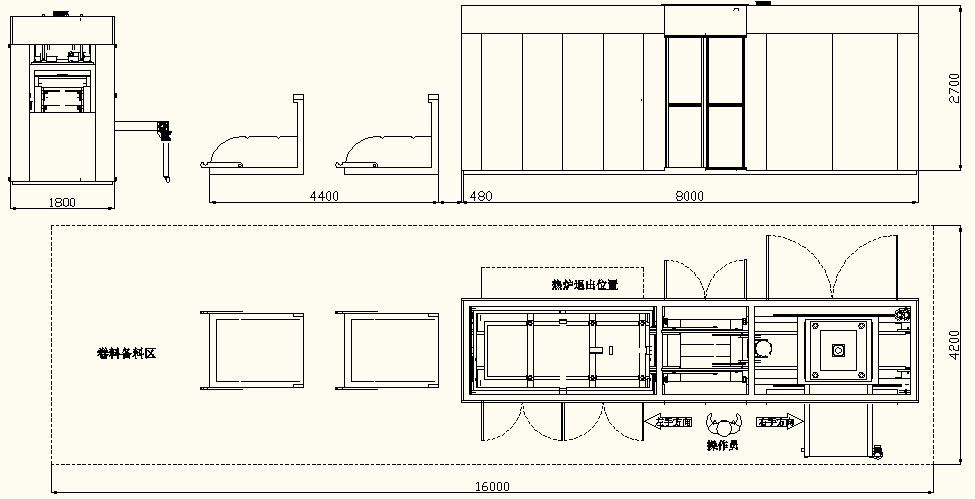

| Overall size (L×W×H) | 8000×1800×2200 mm |

| Weight | 8000KG |

| Remark: We can provide customized machine according to user’s requirement.Considering the development of machine, all data and pics is for reference only | |

3. Working flow:

4. Installation environment:

Avoid direct sunlight, moisture or dusty places; machine should be placed on a solid and flat floor. Check whether the floor loading capacity meets the requirements if install the machine on the second floor or above, place the machine on the beam of the floor so that the gravity is evenly distributed. There is a heating device in the machine, the material will volatilize harmful gases during the heating process, therefore, the machine should be placed in a ventilated place, and above 1500mm away from the wall for easy maintenance.

5. Electronic control method and requirements:

5.1 Power supply: Three-phase five-wire system, i.e., three-phase power supply, one-phase ground wire, and one-phase neutral wire.

5.2 Control requirements: The control system should be away from flammable, explosive, high temperature, high humidity and high corrosion area. The control cabinet should have good heat dissipation conditions. All wiring must be higher than the ground and cannot be directly attached to the ground. The control system is placed at the place where the operator can easily operate and observe. The equipment installed a necessary emergency stop switch. Machine has overload protection and short circuit protection function. When the circuit of the machine hits the shell, the control system cuts off the power supply within 0.1 second.

6. Installation requirements:

Main power: 3P 380V AC 50/60Hz or customized, in total 100KW.

Water supply: water inlet pipe (inner diameter Φ15mm)

Air supply: air inlet (inner diameter Φ32mm)

Air compressor: At least 15KW

Exhausting: at least 1.8m3/min Air pressure: 0.6-0.8Mpa

7. Configuration List:

| Item | Parts Name | Model/Specification | Origin | Brand | Qty |

| 1 | Vacuum Pump | R 5 RA 0100F Pumping speed:100m3/h3KW | Germany | BUSCH | 1set |

| 2 | Air Filter Regulator Lubricator Combination | AC30C-B | Japan | SMC | 1pc |

| 3 | Servo Motor | MSME302GCG3KW | Japan | Panasonic | 1pc |

| 4 | Far infrared ceramic heating brick (upper & lower heater box) | 650W HLF/S 122mm X 122mm | Germany | Elstein | 100pcs |

| 5 | Temperature Controller Module(Solid State Relay) | ZKC-6-36 | Aoyi | China | 100pcs |

| 6 | PLC | FP-XH C60T | Japan | Mitsubishi | 1set |

| 7 | Touch Screen | 10 inch | Japan | Mitsubishi | 1set |

| 8 | Solenoid Valve | 4HA219G3/8 | Japan | CKD | 10pcs |

| 9 | Pneumatic Control Valve | ASC300-15G1/2 | Taiwan | AirTAC | 6pcs |

| 10 | Pneumatic Control Valve | 4F510-15 | Japan | CKD | 1pc |

| 11 | Normally Closed Brass Solenoid Valve | AB21-02 | Japan | CKD | 3pcs |

| 12 | Vacuum Type Solenoid Valve | ADK11-15A | Japan | CKD | 1pc |

| 13 | Limit Switch | WLCA2-2 | Japan | Omron | 6pcs |

| 14 | Intermediate Relay | RXM2LB2BD | France | Schneider | 32pcs |

| 15 | Heat Resistant Wire | 1.5mm2 | Japan | KURABE | 5roll |

| 16 | Magnetic Contactor | LRE12 | France | Schneider | 3pcs |

| 17 | Magnetic Contactor | LC1E12 | France | Schneider | 4pcs |

| 18 | MCCB (Moulded Case Circuit Breaker) | C120H D125 | France | Schneider | 1pc |

| 19 | Frequency Converter | VFD-M Applicable motor:3.7KW | Taiwan | DELTA | 1pc |

| 20 | Frequency Converter | VFD-EL Applicable motor:0.75KW | Taiwan | DELTA | 2pc |

| 21 | Induction Motor | 5IK90GU-CF | Taiwan | ZD | 2pcs |

| 22 | Air Cylinder | Φ1Φ80mm Φ63mmΦ50mm | China | Zhicheng | 2pcs Φ80mm 2pcs Φ63mm 2pcs Φ50mm |

| 23 | Mold Table Driven | Air Cylinder +Crank Arm & Connecting Rod | China | AirTacLISN | 6pcs |

| 24 | Hydraulic Unit for Cutting Station | Oil tank:150L 7.5KW | Taiwan | YUTIEN | 1set |

| Heating system: 650W far infrared ceramic heating bricks | |||||

| Temperature control system: Independent heating zones, controlled by PLC, has memory function | |||||

| Stacking system: Auto stacking, auto counting | |||||

Layout drawings:

Products reference photo:

Pressure & Vacuum forming aluminum mold:

COPYRIGHT © SHANGHAI LISN MACHINERY CO., LTD. ALL RIGHTS RESERVED | Sitemap |