- E-mail: jason@lisn-machinery.com

- Tel: +86 185 1618 2855

1). PLC control system with touch screen

2). Independently controllable heating zones

3). Pneumatically powered clamp frame

4). Automatic cooling system with cooling fans, industrial chiller

5). Automatic vacuum forming system

6). Steel components coated with polyurethane

7). Far infrared ceramic heating bricks or Halogen heater tubes is optional. Halogen heater tube provides rapid heat response with a greater range of control to form challenging shapes and material, infrared ceramic heating brick has longer service life.

PRODUCT DESCRIPTION

Machine video on Youtube:

Application:

The material such as HDPE, ABS, PP, PE, PS, PC, PVC, EPS, HIPS, PET in thick sheet could be processed by this machine, it is an ideal vacuum forming machine for automobile parts like car foot mat, car trunk mat, pickup bedliner, car bumper, plastic containers, plastic pallet, plastic helmet, plastic covers, bathtub, suitcase, apparatus shell, instrument panel, refrigerator inner liners, etc.

1. Overview:

This machine consists of Heating system, Forming system, Vacuum system, Pneumatic system, Cooling system and Control system with reasonable structure. To achieve cost-effective, the design of this machine is optimized, its production speed is fast and 50% energy saving. It is easy to operate with HMI. The machine has acquired a number of national patents, it can be customized according to customers' requirement.

1.1 Basic units:

1). PLC control system with touch screen

2). Independently controllable heating zones

3). Pneumatically powered clamp frame

4). Automatic cooling system with cooling fans, industrial chiller and spray guns

5). Automatic vacuum forming system

6). Steel components coated with polyurethane

7). Far infrared ceramic heating bricks or Halogen heater tubes is optional. Halogen heater tube provides rapid heat response with a greater range of control to form challenging shapes and material, infrared ceramic heating brick has longer service life.

1.2 Main features:

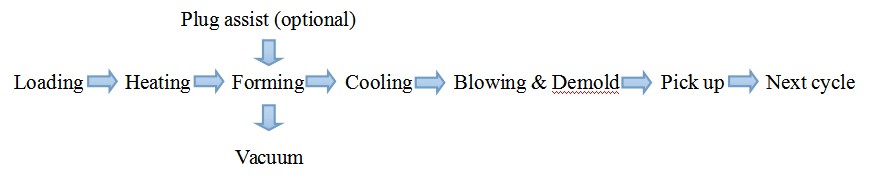

1). Processing flow: Manual Loading Sheet → Clamping Frame Fall → Heating → Pre-stretching → Mold Rise & Vacuum Forming → Cooling → Air Blowing & Releasing from mold → Clamping Frame Rise → Manual Pickup Product.

2). This machine consist of Heating system, Forming system, Vacuum system, Pneumatic system, Cooling system and Control system.

3). Heating & temperature control system: Adopts fully enclosed furnace to reduce heat loss. Adopts Halogen heater tubes with independent temperature controller to ensure the sheet is heated uniformly over its entire surface area and throughout its thickness. Temperature controller for the halogen heater tubes is integrated circuit voltage regulator, means "one to one" control mode, different voltage acquires different temperature. The voltage is PLC controlled and voltage setting is operated on touch screen.

4). Sheet level (Auto-level): A photoelectric beam (photoelectric eye) is activated under the sheet during the heating cycle. If the sheet sags down and breaks the beam, then a small amount of air is injected into the bottom chamber under the sheet, thus lifting the sheet to stop it from sagging until the sheet clears the beam.

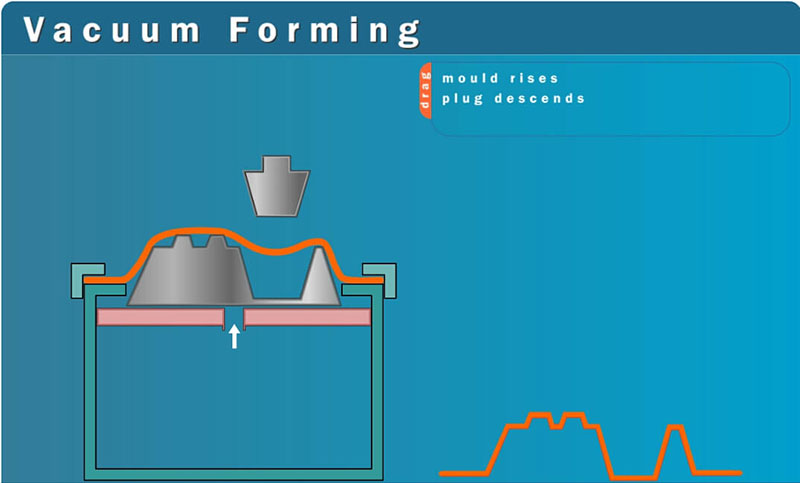

5). Plug assist is optional: Plug assisted vacuum forming is used when straight vacuum forming is unable to distribute the thermoplastic sheet evenly to all areas of the mold. Where a deep draw is required, a device know as top plug is used to push the sheet into the mold before the vacuum is applied to help spread the sheet out more evenly.

6). Cooling system equipped with air-cooled industrial chiller, spray gun and low noise centrifugal fan. Spraying mist is available whereby nozzles are attached to the fans and a fine mist of chilled water is directed onto the sheet.

7). Apply air pressure to release the molding from the mold, damage of the molding in the releasing process is avoided.

8). Machine cycle status is clearly visible at a glance and all parameters can be adjusted in real time without interrupting the current cycle.

9). The PLC program offers saved memory for project to project recognition, that means when processing the same project in next time, there is no need to set the operating parameters again, just touch the project name or project code.

10). Imported electrical and pneumatic components from International well-know manufacturer make the machine features reliable quality and wearing well.

2. Main technical parameters:

| Model | ADF-1000 |

| Applicable material | HDPE, ABS, PP, PE, PS, PC, PVC, EPS, HIPS, PET |

| Max forming length | 2500 mm |

| Max forming width | 2500 mm |

| Forming height | 800 mm |

| Thickness of sheet | 2.0~10.0 mm |

| Power supply | 3P 380V AC 50Hz or customized |

| Control power supply | 24V, DC |

| Max consumed power | 150KW |

| Air pressure | 0.6-0.8 Mpa |

| Mold table driven by | 3.5KW inverter motor |

| Heaters driven by | 2×0.75KW inverter motor |

| Forming method | Vacuum forming |

| Vacuum pump | V-VC 202 (B) Pumping speed: 200m3/h, Power: 5.5KW |

| Working speed | 7 min/cycle (For pickup bedliner) |

| Overall size (L×W×H) | 6000×3700×2800 mm |

| Remark: We can provide customized machine according to user's requirement.Considering the development of machine, all data and pics is for reference only | |

3. Working flow:

4. Installation environment:

Avoid direct sunlight, moisture or dusty places; machine should be placed on a solid and flat floor. Check whether the floor loading capacity meets the requirements if install the machine on the second floor or above, place the machine on the beam of the floor so that the gravity is evenly distributed. There is a heating device in the machine, the material will volatilize harmful gases during the heating process, therefore, the machine should be placed in a ventilated place, and above 1500mm away from the wall for easy maintenance.

5. Electronic control method and requirements:

5.1 Power supply: Three-phase five-wire system, i.e., three-phase power supply, one-phase ground wire, and one-phase neutral wire.

5.2 Control requirements: The control system should be away from flammable, explosive, high temperature, high humidity and high corrosion area. The control cabinet should have good heat dissipation conditions. All wiring must be higher than the ground and cannot be directly attached to the ground. The control system is placed at the place where the operator can easily operate and observe. The equipment installed a necessary emergency stop switch. Machine has overload protection and short circuit protection function. When the circuit of the machine hits the shell, the control system cuts off the power supply within 0.1 second.

6. Installation requirements:

Main power: 3P 380V AC 50Hz or customized, in total 150KW.

Water supply: water inlet pipe (inner diameter Φ15mm)

Air supply: air inlet (inner diameter Φ32mm)

Air compressor: At least 15KW

Exhausting: at least 1.8m3/min

Air pressure: 0.6-0.8Mpa

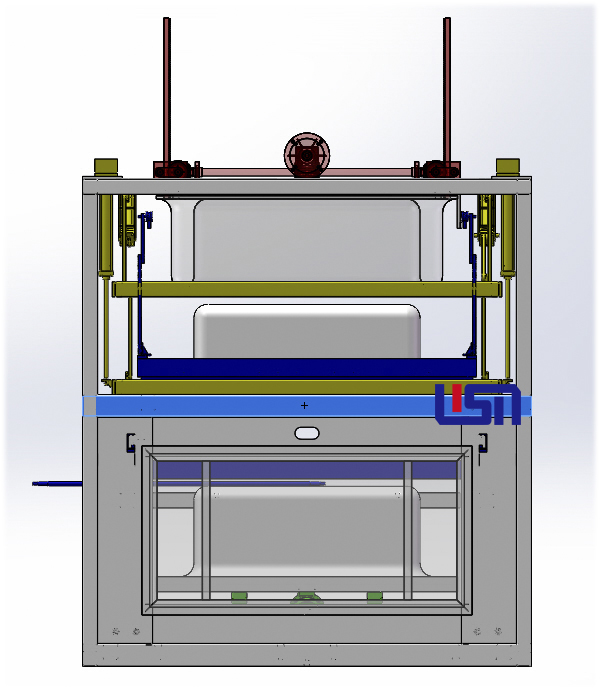

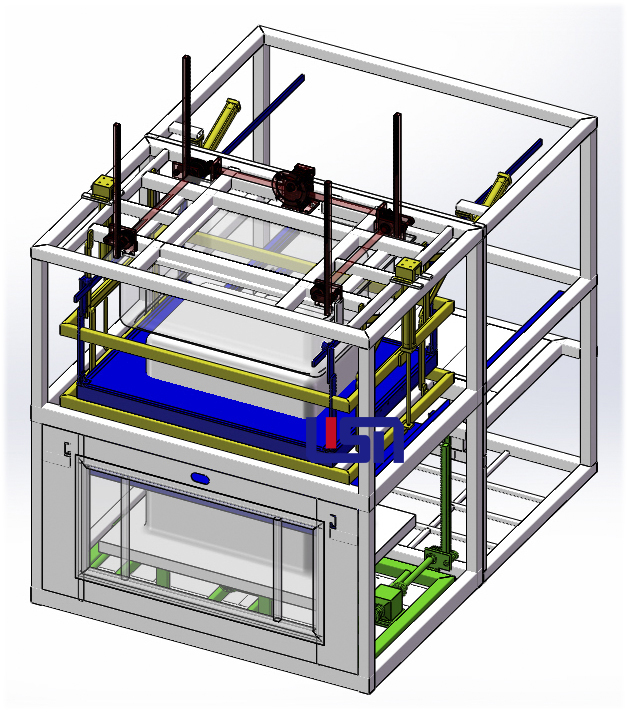

3D drawings:

Product reference photo: (HDPE Pickup Bedliner)

Pickup Bedliner Aluminum Vacuum Forming Mold reference photo:

Demo of Plug Assist: (Plug assisted vacuum forming is used when straight vacuum forming is unable to distribute the thermoplastic sheet evenly to all areas of the mold. Where a deep draw is required, a device know as top plug is used to push the sheet into the mold before the vacuum is applied to help spread the sheet out more evenly.)

Plug Assist Video:

COPYRIGHT © SHANGHAI LISN MACHINERY CO., LTD. ALL RIGHTS RESERVED | Sitemap |