- E-mail: jason@lisn-machinery.com

- Tel: +86 185 1618 2855

1). PLC control system with touch screen

2). Independently controllable heating zones, heated by far infrared ceramic heating bricks

3). Pneumatically powered clamp frame

4). Automatic cooling system with industrial chiller and spray guns

5). Automatic vacuum forming system

6). Steel components coated with polyurethane

PRODUCT DESCRIPTION

Machine video on Youtube:

Application:

The material such as PP, PE, PS, PVC, PET, PETG, EPS, HIPS, HDPE, PMMA in soft film could be processed by this machine, it is an ideal vacuum forming machine for blisters, clamshell, plastic containers, disposable lunch box, fruit trays, egg trays, dishes, bowls, lids, medical packaging such as ampoule trays and vial trays, etc.

1. Outline:

The equipment consist of heating system, forming system, vacuum system, pneumatic system, cooling system and control system with reasonable structure. It is designed in line with the principle of energy saving and its production speed is 60% faster and 50% energy saving than single station thick sheet vacuum forming machine. It is easy to operate with HMI. The machine has acquired a number of national patents, it can be customized according to customers' requirement.

1.1 Basic units:

1). PLC control system with touch screen

2). Independently controllable heating zones, heated by far infrared ceramic heating bricks

3). Pneumatically powered clamp frame

4). Automatic cooling system with industrial chiller and spray guns

5). Automatic vacuum forming system

6). Steel components coated with polyurethane

1.2 Main features:

1). Feeding system: Auto feeding with inverter motor or servo motor driven, high speed, accurate and stable, digital length adjustment. Adopts special chain rail to ensure no deviation and vibration, wearing well.

2). Auto temperature control system using intelligent compensation control, heating up fast, stable, low energy consumption and with long life heating bricks.

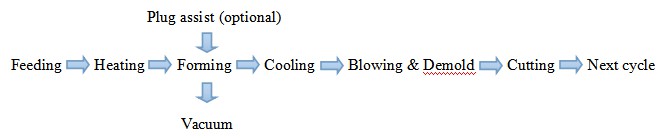

3). Processing flow: Auto Feeding → Heating → Forming → Cooling → Air Blowing & Releasing from mold → Cutting.

4). This machine consists of Heating system, Forming system, Vacuum system, Pneumatic system, Cooling system and Control system.

5). Two-stage vacuum sucking to ensure the thick sheet is easy to form and to improve the molding quality.

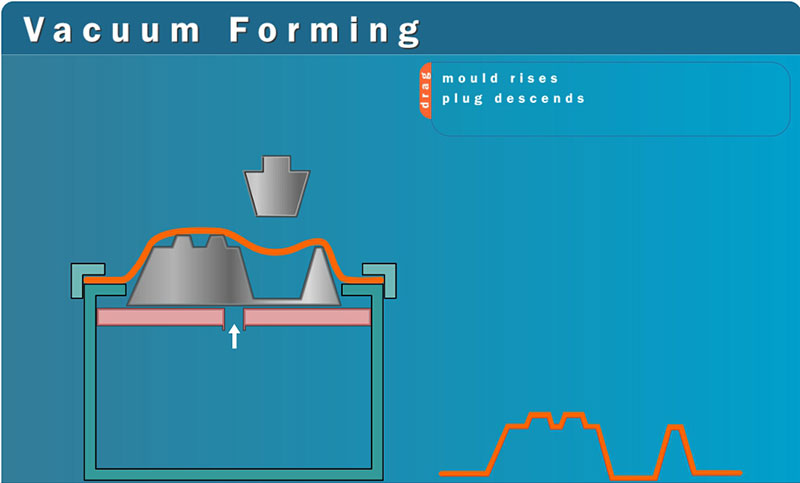

6). Plug assist is optional: Motorised synchronised plug assist system ensures uniform drawing. Plug assisted vacuum forming is used when straight vacuum forming is unable to distribute the thermoplastic sheet evenly to all areas of the mold. Where a deep draw is required, a device know as top plug is used to push the sheet into the mold before the vacuum is applied to help spread the sheet out more evenly.

7). Apply air pressure to release the molding from the mold, damage of the molding in the releasing process is avoided.

8). Machine cycle status is clearly visible at a glance and all parameters can be adjusted in real time without interrupting the current cycle.

9). The PLC program offers saved memory for project to project recognition.

10). Imported electrical and pneumatic components from International well-know manufacturer make the machine features reliable quality and wearing well.

2. Main technical parameters:

| Model | ACF-710 |

| Applicable material | PP, PE, PS, PVC, PET, PETG, EPS, HIPS, HDPE, PMMA |

| Max forming area | 710×1200 mm |

| Max forming height/depth | 220 mm |

| Sheet width | 470~760 mm |

| Thickness of sheet | 0.2~2.0 mm |

| Max. stroke of chassis | 300 mm |

| Power supply | 3P 380V AC 50/60Hz or customize |

| Control power supply | 24V, DC |

| Max consumed power | 36KW |

| Air pressure | 0.6-0.8 Mpa |

| Bottom mold table driven by | Air cylinder + crank armMax drive 500KG |

| Forming method | Vacuum forming |

| Vacuum pump | V-VC 100 (B) Pumping speed: 100m3/h, Power: 3.0KW |

| Heating element | Far infrared ceramic heating brick |

| Working speed | 5~8 cycle/min |

| Overall size (L×W×H) | 7300×1500×2200 mm |

| Remark: We can provide customized machine according to user's requirement.Considering the upgrade of machine, all data and pics is for reference only | |

3. Working flow:

4. Configuration List:

| Configuration List | |||||

| Item | Parts Name | Model/Specification | Origin | Brand | Qty |

| 1 | Vacuum Pump | V-VC 100 (B) Pumping speed:100m3/h3.0KW | Germany | Elmo Rietschle | 1set |

| 2 | Vacuum Gauge | Auto Gauge | China | Tianhu | 1pc |

| 3 | Industrial Water Cooled Chiller | 3HP | China | Hengxin | 1pc |

| 4 | Spray Gun | A-100 | Japan | Meiji | 10pcs |

| 5 | Centrifugal Fan | 150FLJ7-2N2220V 330W 50Hz | China | Minor | 4pcs |

| 6 | Electric Shrinking Mold Base | 560×1230mm | China | Ming Shan Yu | 1pc |

| 7 | Air Cylinder | Φ160mm Φ125mm Φ80mm Φ63mmΦ50mm | China | Zhicheng | 1pc Φ125mm 2pcs Φ80mm 2pcs Φ63mm 5pcs Φ50mm |

| 8 | Solenoid Valve | 4HA219G3/8 | Japan | CKD | 6pcs |

| 9 | Pneumatic Control Valve | ASC300-15G1/2" | Taiwan | AirTAC | 7pcs |

| 10 | Pneumatic Control Valve | 4F510-15 | Japan | CKD | 2pcs |

| 11 | Normally Closed Brass Solenoid Valve | AB21-02 | Japan | CKD | 2pcs |

| 12 | Vacuum Type Solenoid Valve | ADK11-15A | Japan | CKD | 1pc |

| 13 | Copper Gate Valve | DN15 DN25 | China | Baoluolai | 6pcs |

| 14 | Air Filter Regulator Lubricator Combination | AC30C-B | Japan | SMC | 1set |

| 15 | Far infrared ceramic heating brick (Top heater)(Push out heater box) | 500W 220V120mm X 120mm | Taiwan | Infrapara | 48pcs |

| 16 | Temperature Controller (Voltage Regulator) | NZKG-2 | China | AISET | 48pcs |

| 17 | Limit Switch | K44GR | Japan | Omron | 3pcs |

| 18 | Inductive Proximity Switch | PR18-8DN | Korea | Autonics | 4pcs |

| 19 | PLC | B1-40MR2-AC | Taiwan | FATEK(SIEMENS is optional) | 1set |

| 20 | Touch Screen | 10 inch | Taiwan | Unicon(SIEMENS is optional) | 1set |

| 21 | Intermediate Relay | RXM2LB2BD | France | Schneider | 20pcs |

| 22 | Heat Resistant Wire | 1.5mm2 | Japan | KURABE | 4roll |

| 23 | Magnetic Contactor | LC1D12 | France | Schneider | 7pcs |

| Magnetic Contactor | LC1D65A | France | Schneider | 1pc | |

| 24 | MCCB (Moulded Case Circuit Breaker) | C120H D125 | France | Schneider | 1pc |

| 25 | Frequency Converter | VFD-M Applicable motor:3.7KW | Taiwan | DELTA | 1pc |

| 26 | Frequency Converter | VFD-EL Applicable motor:0.75KW | Taiwan | DELTA | 1pc |

| 27 | Rotary Encoder | E40S6-600-3-T-24 | Korea | Autonics | 1pc |

| 28 | Variable-frequency Motor(Three-phase Asynchronous Motor) | YS90L-22.2KW | Sino-German Venture | DEDONG | 1pc |

| 29 | Gear Reducer Motor | 5GN-20K220V, 50Hz | Taiwan | Taili | 2pcs |

| 30 | Servo Motor (Optional) | MSME302GCG3KW | Japan | Panasonic | 1pc |

| 31 | Selector Switch | XB2BD33C | France | Schneider | 6pcs |

| 32 | Pushbutton Switch | XB2BWM41C | France | Schneider | 4pcs |

| Remark: The machine with different Max. forming area has different number of spray gun, heating brick and temperature controller. | |||||

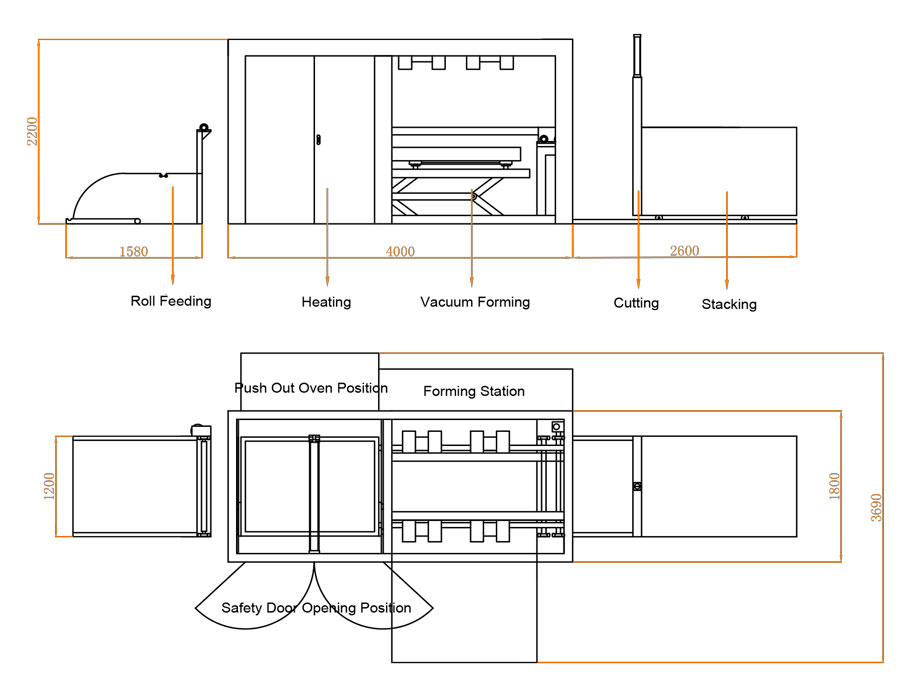

Layout drawings:

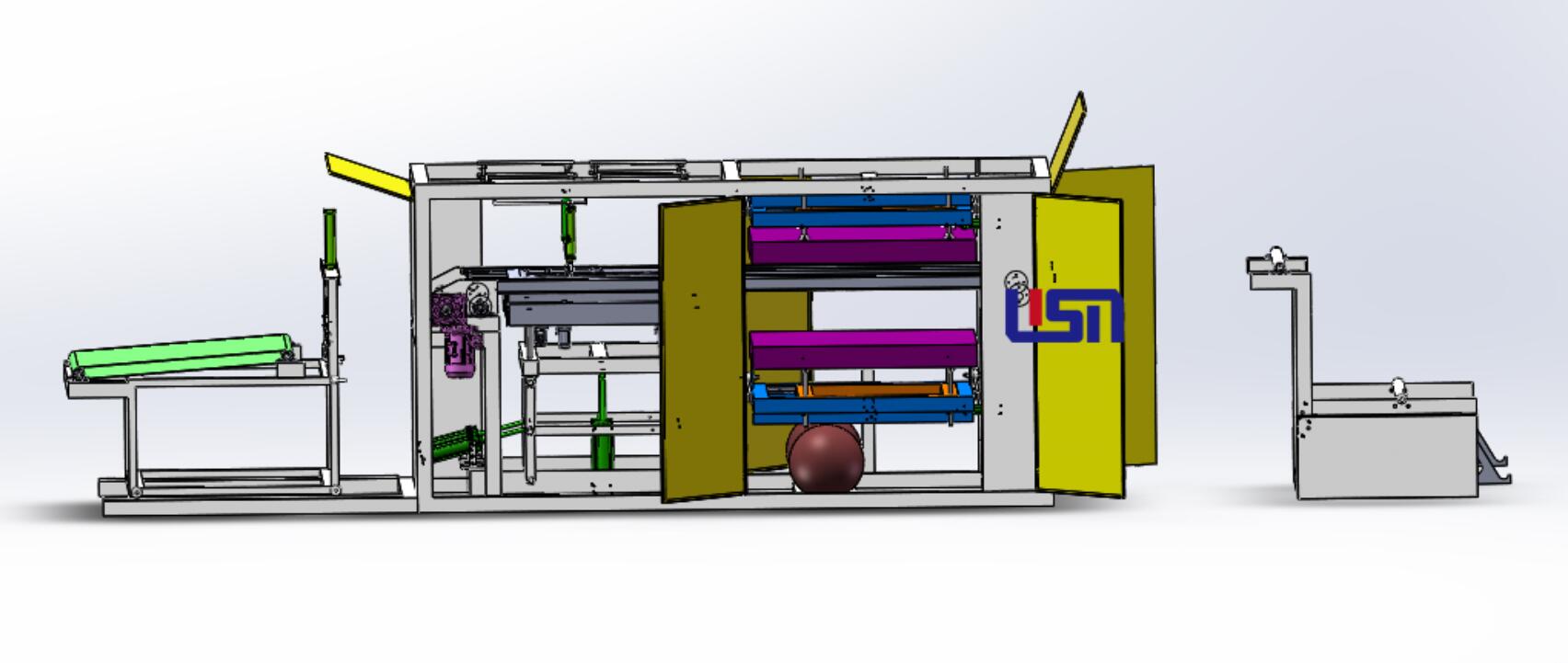

3D drawing:

Demo of Plug Assist: (Plug assisted vacuum forming is used when straight vacuum forming is unable to distribute the thermoplastic sheet evenly to all areas of the mold. Where a deep draw is required, a device know as top plug is used to push the sheet into the mold before the vacuum is applied to help spread the sheet out more evenly.)

COPYRIGHT © SHANGHAI LISN MACHINERY CO., LTD. ALL RIGHTS RESERVED | Sitemap |